- Batteriepilot / Produktionslinie

- Batterielabor Montage

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li-Ion Battery Materials

- kathodenaktive Materialien

- anodenaktive Materialien

- Customized Battery Electrode

- Münze Zelle Materialien

- Lithium-Chip

- zylindrische Zellteile

- Batteriestromkollektoren

- batterieleitende Materialien

- Elektrolyt und Beutel

- Metal Mesh

- Batterieordner

- Trennzeichen und Klebeband

- Aluminiumlaminatfolie

- Nickelstreifen / -folie

- Battery Tabs

- Graphenmaterialien

- Titanium Fiber Felt

- Batterie

- Battery Pack Machine & Compoments

- alle Batteriemontagemaschine

- Batterietester & Analysator

- Battery Safety Tester

- Battery Material Tester

- Walzpresse Maschine

- Metall-Punktschweißgerät

- Vakuummischer Maschine

- Crimp- / Demontagemaschine

- Vakuumiermaschine

- Elektrolytfüllung

- Stapel- / Wickelmaschine

- Elektrodenschneider / -schneider

- Beutelformmaschine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vakuum-Glove-Box

- Öfen

- Coaters

- Hydraulikpresse

- Kugelmühle

- Planetenrührwerk / Mühle

- Labormaschine

- Metallelektrodenschaum

- WhatsApp : +86 13003860308

- E-Mail : David@tmaxcn.com

- E-Mail : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

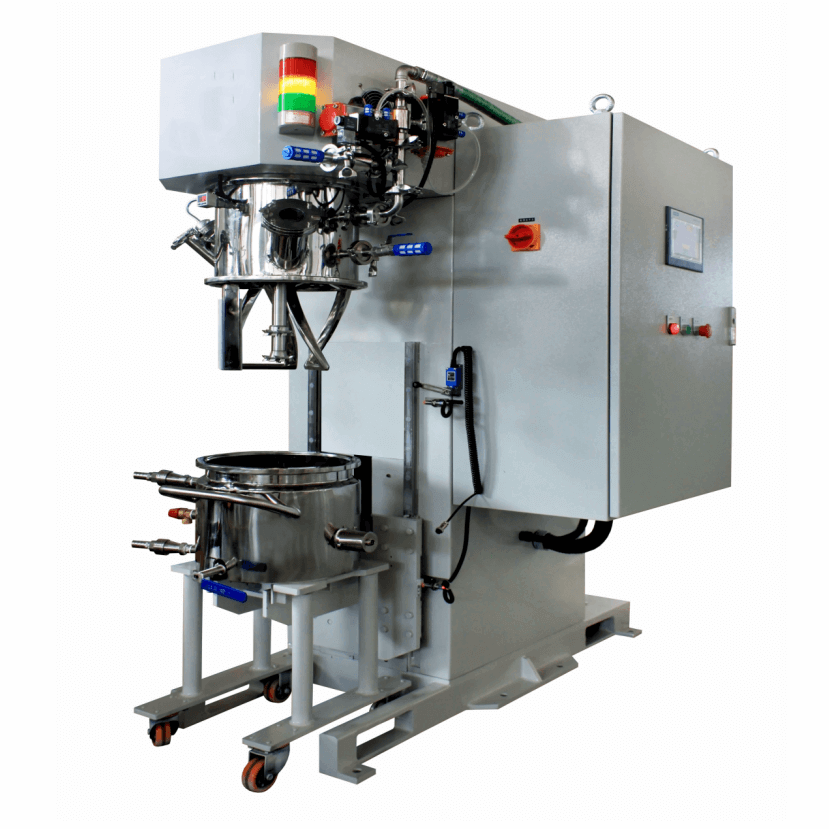

10-Liter-Hochgeschwindigkeits-Vakuummischer mit Planetendispersion für die Batterie-Pilotlinie

Model Number:

TMAX-XFZH10:

XiamneMOQ:

1Zahlung:

L/C D/A D/P T/T Western UnionDelivery Time:

45 days

- WhatsApp : +86 13003860308

- E-Mail : David@tmaxcn.com

- E-Mail : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Vorherige:

5L Vakuum-Planetendispersions-Vakuummischer mit Kühler und VakuumpumpeNächste:

Auto-Roll-to-Roll-Tab-Schweißmaschine

High Speed 10L Planetary Dispersion Vacuum Mixer for Battery Pilot Line

Ⅰ、Equipment features:

Scope of application

1.1The powder and liquid of various common batteries are mixed and dispersed to finally obtain a uniformly mixed battery slurry. Very suitable for highly viscous processes.

1.2Applicable viscosity range≤1,200,000cP

Ⅱ、Main parameters of equipment:

2.1Lower barrel part

2.11Total design volume:16L

2.12 Effective volume:5-10L

2.13 Vessel inner diameter:310mm

2.14 Inner depth of container:220mm

2.15 Container material::Material contact portion 304

2.16 Temperature regulating jacket form: single layer jacket on barrel wall, used for cooling or heating; Single layer jacket at the bottom of the barrel for cooling or heating

2.17 Temperature regulating jacket interface: G3 / 8 ", with quick opening Union, jacket pressure ≤ 0.4MPa

2.18 Temperature regulating jacket circulation system: provided by the customer. It is recommended that the jacket inlet temperature is ≤ 8 ℃, and the cooling water flow is > 3.5l/min

2.19 Discharge form: a G1 / 2 "three piece discharge ball valve at the bottom of the barrel

2.20 Design ambient temperature:-10~+120°C

2.21 Mobile mode: caster Mobile

2.2Mixing parts

2.21Working frequency:5-50hz

2.22 Mixing power:2.2kw

2.23 Agitator speed:11-116rpm

2.24 Planetary case speed:5-53rpm

2.25 Agitator diameter:161mm

2.26 Agitator style: variable section spiral fried dough twist type, 90 ° spiral

2.27 Agitator material:304

2.28 Linear speed of agitator:0.08-0.8m/s

2.29 Number of agitators:2pcs

2.30 Paddle to paddle distance:7.5±2.5mm

2.31Distance between paddle and barrel wall:3+1.5mm

2.32 Distance between paddle and bucket bottom:2.5+1mm

2.3 Dispersed parts

2.31 Working frequency:5-50hz

2.32 Dispersed power:3KW

2.33 Dispersion speed:613-6130rpm

2.34 Diameter of dispersion disc:70mm

2.35 Dispersive disk style: zigzag

2.36 Dispersion disk material:304

2.37 Dispersion linear velocity:2.2-22m/s

2.38 Number of dispersing discs:2

2.39 Number of dispersing shafts: 1

2.4 Wall scraping parts

2.41 Material of wall scraping bracket:304

2.42 Material of wall scraping plate: polytetrafluoroethylene

2.43 Wall scraping speed: consistent with the speed of planetary case

2.44 Whether it is detachable: detachable design (the scraping wall must be removed during high viscosity process)

2.5 Base and lifting parts

2.51 Component material: carbon steel for high rigidity structure

2.52 Lifting mode: electric lifting

2.53 Lifting guide: high precision linear guide

2.54 Lifting stroke:≤440mm

2.6 Upper barrel part

2.61 Upper barrel material:304

2.62 Powder feeding port: DN50 quick assembly with mirror:1 PC

2.63 Liquid feeding port: ISO 1 / 2 "quick loading: 1PC

2.64 Spotlight: DN50 :1 PC

2.65 Vacuum outlet: G1 / 2 "inner wire:1PC

2.66 Exhaust port: shared with vacuum port

2.67 Nitrogen port: G1 / 2 "inner wire:1PC

2.68 Digital vacuum gauge port: M14 * 1.5 internal thread metric thread interface:1PC

2.7 Control system:

2.71 Electrical cabinet: used to place low-voltage electrical components such as frequency converter

2.72 Operation panel: used to place buttons, knobs, touch screens, etc

2.73 Power:AC 3×380V±5﹪,50Hz

2.74 Control mode: electric control

2.75 Power control and speed regulation mode: frequency converter startup and control

2.76 Cooling mode: air cooling

2.77 Operation mode: touch screen operation

2.78 Digital temperature display table: material temperature

2.79 Emergency stop button: 1PC

2.80Alarm system: over temperature alarm, over temperature alarm shutdown, alarm shutdown

2.81 Speed display: touch screen displays speed

2.82 Power indicator: 1PC

2.8 Safety interlock system

2.81 Emergency stop: press the emergency stop switch, and the equipment will stop immediately without any operation.

2.82 Start low-speed mixing: it can rotate while lifting the barrel

2.83 High speed dispersion: the barrel can be turned only when it is raised to the position

2.84 Safety lock during operation: when the machine is running and mixing, the mixing bucket cannot be lowered and opened.

2.85 Prevent vacuum pipeline backflow: special vacuum buffer tank design can effectively prevent vacuum pump oil from backflow to the mixing drum

2.86 Operation fault stop: the frequency converter is equipped with overload, overcurrent, overvoltage, leakage and lack of protection

2.87 Lifting and lowering of mixing bucket: the mixing bucket can only be lifted after it is in place.

2.89 If the mixing drum is not evacuated (normal pressure is not restored), it cannot be lowered.

2.90 The high-speed dispersion can be started only after the mixing bucket is raised in place.

2.91 After the mixing bucket is lifted in place, it is equipped with a locking protection system to prevent the mixing bucket from falling abnormally after rising to the high position during operation.

2.92 In the dry mixing stage, the agitator needs to rotate while lifting the bucket.

2.9 Other instructions

2.91 Temperature measuring probe:Pt100

2.92 Temperature measurement method: the barrel wall mounted temperature measuring head detects the material temperature

2.93 Transmission component bearings: high speed components are imported bearings, and low speed components are domestic bearings

2.94 Oil seal: domestic brand, O-ring for static seal, mechanical seal for dynamic seal.

2.95 Mechanical seal lubricating oil: imported

2.96 Valves: domestic brands

2.97 Vacuum design demand: customers must provide their own vacuum system air extraction:4L/S(2XZ-4)

2.98 Vacuum holding:-0.098Mpa,Keep the pressure higher than -0.085mpa for 24 hours, without leakage into the barrel

2.99 Total power:>5.2kw

2.100 Total weight:about 900kg

2.101 Equipment size:L1530mm*W922mm*H1792mm

2.102 Color:White

2.103 Ground bearing:900kg/㎡

Ⅲ、List of random wearing parts:

SN |

Name |

Specification |

Material |

Qty |

Remark |

1. |

Upper cover sealing rubber ring |

ΦD×ΦN |

silica gel |

1 |

|

2. |

Mirror base sealing ring |

|

silica gel |

2 |

|

3. |

Filler gasket |

|

silica gel |

1 |

|

4. |

High speed mechanical seal |

|

C+SiC |

1 |

|

5. |

High speed synchronous belt |

|

silica gel |

1set |

|

6. |

Scraping plate |

|

Teflon |

1 |

|

7. |

Mirror glass |

|

Tempered type |

2pcs |

|

Ⅳ、Supporting conditions:

SN |

Entry name |

Standard requirements |

1. |

Workshop height |

>2.5M;A certain height is required for machine lifting and maintenance needs are considered; Clean and level |

2. |

Door size: |

Height:>2.5M;Width:>1.5M; To ensure that the machine is transported in and out. |

3. |

Cooling water |

To ensure the cooling requirements, it is better to have a forced cooling water supply system; If insulation is required in winter, hot water supply is required. |

4. |

Heating |

In view of the cold weather in the north in winter, in order to prevent the hydraulic oil for lifting from condensation, it is necessary to ensure the indoor temperature > 20 º C to ensure the smooth lifting of the machine; And ensure the normal operation of the lubrication system。 |

5. |

Installation space |

Refer to the general plan of the scheme for layout. |

6. |

Air source |

5~7 kgf/cm²,100 l/min;Pneumatic pump drive and other occasions. |

7. |

Others |

No corrosive gas, liquid and explosive gas. |

Detailed Images

English

English

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588