- E-Mail : David@tmaxcn.com

- E-Mail : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

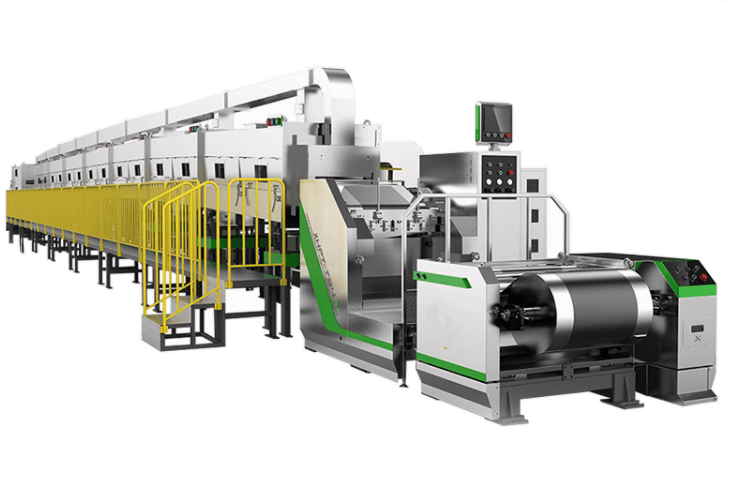

Apologies for the oversight. Here's a more detailed list of prismatic battery fabrication line and their mechanical structures:

1.Electrode Preparation Equipment:

Prismatic battery fabrication machine Coating Machines: Consist of a coating head, uniform roller, and feeding system. The coating head applies electrode materials onto current collectors using methods such as spraying or doctor blade coating. The uniform roller ensures even distribution of the coating material, while the feeding system controls the supply of the coating material.

Slitting Machines: Comprise a feeding system, cutting blade, and tension control system. The feeding system feeds the coated electrode material to the cutting blade, which precisely cuts the electrode material at the desired speed and position. The tension control system maintains appropriate tension to prevent material damage.

Electrode Drying Ovens: Include a heating chamber and exhaust system. The heating chamber evaporates solvents from the electrode material through temperature control and ventilation, ensuring the drying and adhesion of the electrode material.

2.Electrolyte Dispensing Equipment:

Dispensing Systems: Consist of electrolyte storage tanks, pumps, and precision metering systems. The electrolyte is transferred from the storage tanks to the precision metering system via pumps, ensuring accurate electrolyte volume and flow.

Automated Pipetting Stations: Include automated pipettors, sample stages, and precision control systems. The automated pipettors distribute the electrolyte at preset volumes and positions, facilitating precise dispensing.

3.Cell Assembly Equipment:

Stacking Machines: Comprise stacking arms, alignment systems, and compression mechanisms. The stacking arms position and stack the prepared electrode layers and separators with precise alignment. The compression mechanisms apply pressure to ensure a tight bond between the layers.

Laminating Machines: Consist of a heating system, pressure rollers, and conveyor belts. The heating system provides controlled temperature, while the pressure rollers and conveyor belts apply pressure and transfer heat to laminate the electrode layers and separators together.

Cell Tab Welding Machines: Include welding heads, positioning systems, and power sources. The welding heads perform the welding process to connect the cell tabs to the current collectors, establishing electrical connections.

4.Cell Formation and Testing Equipment:

Formation Chambers: Provide controlled temperature and current conditions for prismatic cells during the formation process. These chambers ensure the conditioning and stabilization of cell performance.

Cell Testing Systems: Comprise testing fixtures, measurement instruments, and data acquisition systems. These systems perform various tests such as capacity measurement, cycling tests, and impedance analysis to evaluate the performance and characteristics of prismatic cells.

5.Cell Packaging Equipment:

Cell Encapsulation Machines: Include sealing mechanisms, vacuum chambers, and lid placement systems. These machines encapsulate prismatic cells in airtight containers by sealing them with precise pressure and temperature control. Vacuum chambers remove air and moisture before sealing, ensuring a proper seal.

Laser Welding Machines: Utilize laser beams and positioning systems to perform precise welding for sealing the cell containers. The laser welding process ensures reliable and hermetic sealing.

6.Quality Control and Inspection Equipment:

Vision Inspection Systems: Comprise cameras, image analysis algorithms, and conveyors. These systems inspect and verify the quality of cell components, including electrode layers, alignments, and welds, using imaging and analysis techniques.

Thickness Gauges: Utilized to measure the thickness of electrode layers and ensure uniformity throughout the prismatic battery fabrication plant. These gauges use contact or non-contact methods to obtain accurate measurements.

These equipment types, with their respective mechanical structures, are critical for the efficient and precise fabrication of prismatic cells on a larger scale, enabling automation, accuracy, and consistency in the manufacturing process.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com