- Batteriepilot / Produktionslinie

- Batterielabor Montage

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li-Ion Battery Materials

- kathodenaktive Materialien

- anodenaktive Materialien

- Customized Battery Electrode

- Münze Zelle Materialien

- Lithium-Chip

- zylindrische Zellteile

- Batteriestromkollektoren

- batterieleitende Materialien

- Elektrolyt und Beutel

- Metal Mesh

- Batterieordner

- Trennzeichen und Klebeband

- Aluminiumlaminatfolie

- Nickelstreifen / -folie

- Battery Tabs

- Graphenmaterialien

- Nickel Felt

- Titanium Fiber Felt

- Batterie

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- alle Batteriemontagemaschine

- Batterietester & Analysator

- Battery Safety Tester

- Material Characterization Tester

- Walzpresse Maschine

- Metall-Punktschweißgerät

- Vakuummischer Maschine

- Crimp- / Demontagemaschine

- Vakuumiermaschine

- Elektrolytfüllung

- Stapel- / Wickelmaschine

- Elektrodenschneider / -schneider

- Beutelformmaschine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vakuum-Glove-Box

- Öfen

- Coaters

- PVD Coater

- Hydraulikpresse

- Large Press Machine

- Planetenrührwerk / Mühle

- Kugelmühle

- Labormaschine

- Cutting Machine

- Metallelektrodenschaum

- WhatsApp : +86 18659217588

- E-Mail : David@tmaxcn.com

- E-Mail : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Projekte

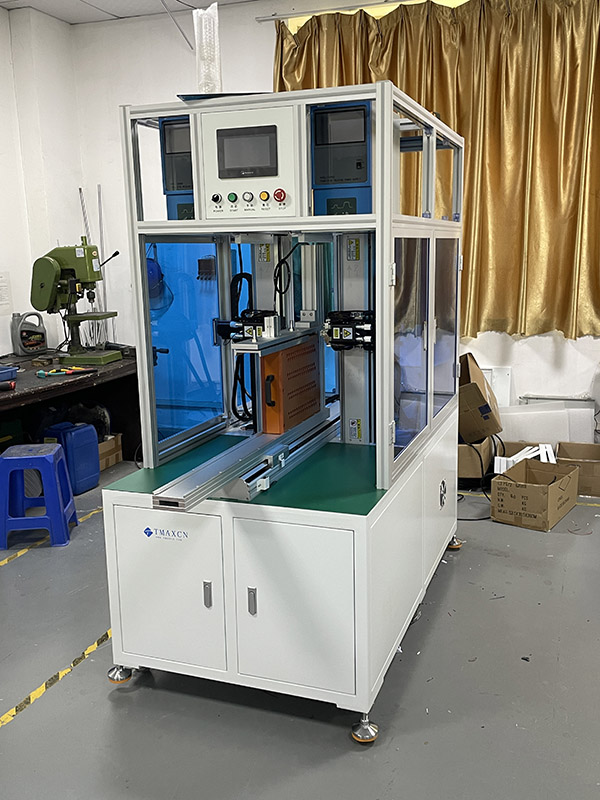

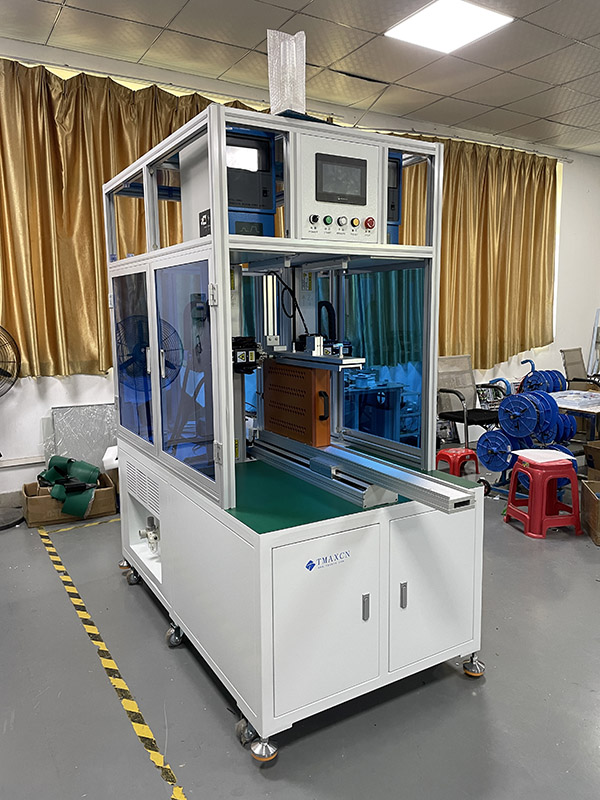

TMAX Completes Custom Double-Sided Spot Welding Machine for UK Client

TMAX is pleased to announce the successful assembly of a custom large double-sided spot welding machine for our esteemed UK client. This machine, with a stroke range of 600*1200mm, is specifically designed to meet the production needs of large-sized battery packs.

TMAX remains committed to continuous innovation and the advancement of battery manufacturing technology to meet the growing global demand for high-quality battery products.

2024-07-11

TMAX Completes Custom Double-Sided Spot Welding Machine for UK Client

TMAX is pleased to announce the successful assembly of a custom large double-sided spot welding machine for our esteemed UK client. This machine, with a stroke range of 600*1200mm, is specifically designed to meet the production needs of large-sized battery packs.

The double-sided spot welding machine plays a crucial role in the manufacturing of cylindrical battery packs, which are widely used in electric vehicles and energy storage systems due to their high energy density and stability.

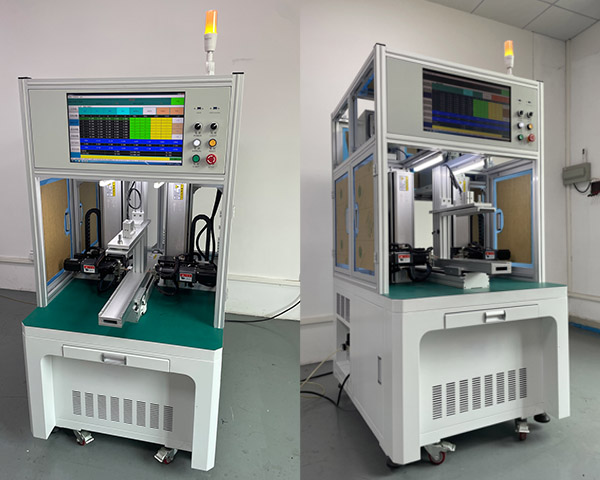

In addition to this custom machine, TMAX is launching a new automatic welding machine equipped with advanced control technology and upper-level computer integration. This innovative device offers higher automation and production efficiency, providing customers with more choices and optimized solutions.

→ Double-Side Automatic Welder with PC

→ Single-Side Automatic Welder with PC

TMAX remains committed to continuous innovation and the advancement of battery manufacturing technology to meet the growing global demand for high-quality battery products.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com