- E-Mail : David@tmaxcn.com

- E-Mail : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

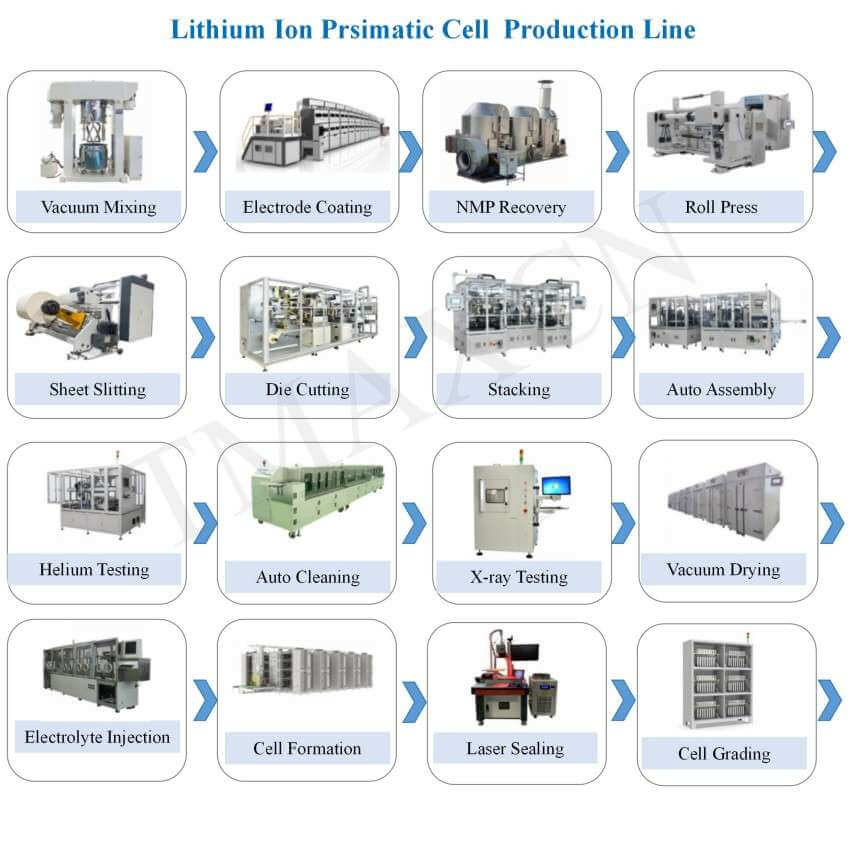

With the development of new energy vehicles, there are more and more types of new energy vehicle batteries, such as lithium iron phosphate batteries, lithium manganate batteries, ternary lithium batteries, etc. In order to meet production needs, many automobile battery manufacturers have adopted new energy vehicle battery assembly lines for automated production. Below, I will introduce the new energy vehicle battery assembly lines to you.

The new energy battery assembly line has achieved automation, informatization, and standardization of the battery assembly production process, from cell loading to PACK unloading, and largely adopts automated production. This production line uses flexible connections, and the entire process can be imported into the MES system for management, material parameters, and manufacturing data through data transfer interfaces. Quality information is stored in a timely manner and can be traced at any time, while fully considering and reserving space and interfaces for automatic upgrades.

The new energy vehicle battery assembly line consists of a complete assembly line consisting of non-standard assembly equipment, non-standard conveyor line bodies, automatic load transfer and lifting machinery, loading and unloading robots, testing equipment, and automated human-machine control systems.

Taking the square PACK battery pack solution as an example: fully automatic Car battery manufacturing line

square (hard shell) battery module assembly wiring, suitable for square aluminum shell battery module assembly, capable of high-precision automatic feeding, cell processing, module assembly, module stacking, busbar to shell welding, and key data detection.

Advantages of New Energy Vehicle Battery Assembly Line:

1. Rationality

The design of the battery assembly line fully considers ergonomics, reduces manual labor intensity, and allows for free layout of buses and logistics according to the site.

2. Compatibility

The battery assembly line is equipped with servo fixtures and a tray quick change design, which is compatible with the replacement of battery cells and modules during the working process.

3. Intelligence

The battery assembly line can be set by the main control unit that manages the entire production line, displaying production data centrally on the main display screen, or can be operated independently in the unit equipment.

4. Humanization

The Car battery production line

has a simple interface and is easy to operate, greatly reducing the product development cycle, improving production efficiency and energy utilization, ensuring product hygiene and safety, and meeting industry requirements.

ru

ru English

English

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com