- E-Mail : David@tmaxcn.com

- E-Mail : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

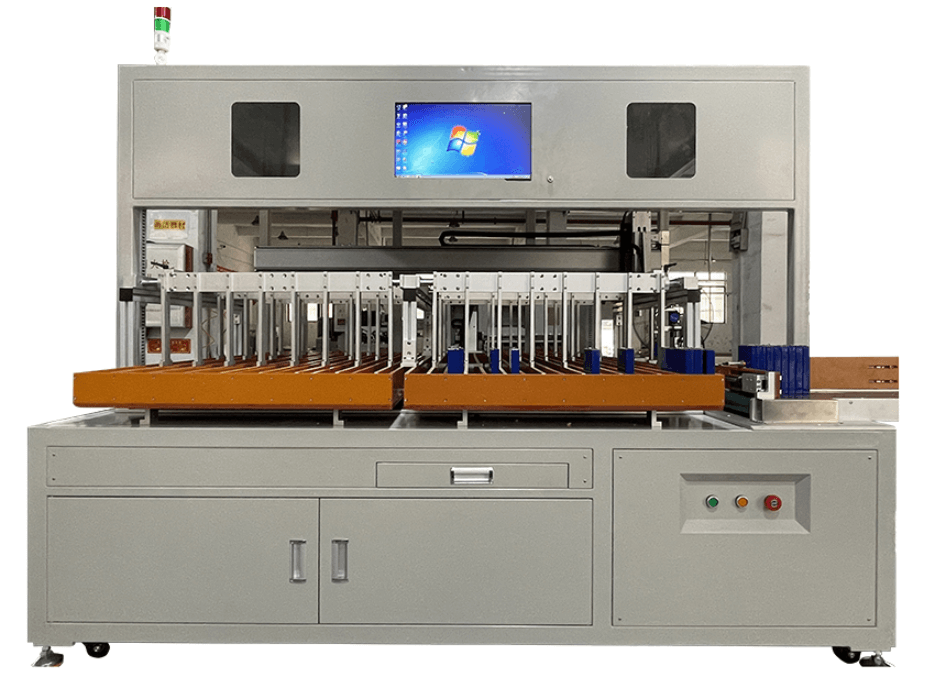

A prismatic cell manufacturing machine is a specialized piece of equipment designed to produce prismatic lithium-ion battery cells. The machine typically consists of several stages, each of which has its own specialized equipment. Here are some of the typical components that may be included in a prismatic cell manufacturing machine:

Material preparation equipment: This equipment is used to prepare the materials used in the battery, including the electrode materials, separator materials, and electrolyte.

1. Electrode manufacturing equipment: This equipment is used to create the positive and negative electrodes, typically by applying an active material to a current collector material.

2. This equipment is used to apply a coating of active material to the current collector.

3. Electrode Calendering machine : This equipment is used to compress the active material onto the current collector.

4. Cell assembly equipment: This equipment is used to assemble the positive and negative electrodes, separator, and electrolyte into a complete battery cell.

5. Formation equipment: This equipment is used to form the battery cell and establish its initial charge.

6. Sealing equipment: This equipment is used to seal the completed battery cell to prevent electrolyte leakage.

Prismatic cell manufacturing line may also include a range of additional equipment, such as thermal processing equipment to manage temperature and humidity, and testing equipment to ensure that the final product meets quality standards. The precise configuration of the equipment will depend on the specific needs of the battery manufacturer.

Overall, prismatic cell manufacturing equipment are essential for the production of high-quality lithium-ion batteries, which are used in a wide range of applications, including electric vehicles, grid energy storage systems, and portable electronics.

ru

ru English

English

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com